Bloomberg News

CHIPS Act Turns 2, Stays on Track

[Stay on top of transportation news: Get TTNews in your inbox.]

The Biden administration is nearly finished dividing up $39 billion in grants under the CHIPS and Science Act, the landmark bipartisan legislation aimed at revitalizing the domestic semiconductor industry. The bigger test still lies ahead.

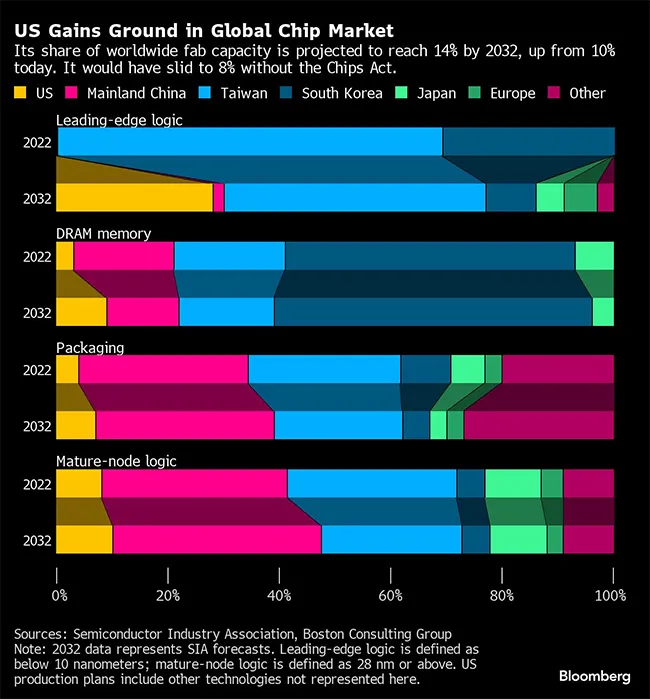

The CHIPS Act, enacted two years ago Aug. 9, is the nation’s most audacious foray into industrial policy since World War II. It’s essentially a bet that four companies — Intel Corp., Micron Technology Inc., Taiwan Semiconductor Manufacturing Co. and Samsung Electronics Co. — can bring sophisticated chip production back to the U.S. In a sign of the ambition, one explicit goal is making a fifth of the world’s most advanced processors by 2030, up from roughly zero today.

The U.S. is in many ways on track, but it has been no simple task. Hundreds of firms spent months haggling over the money. Even U.S. officials themselves have disagreed over which parts of the chip economy need the most help. They opted to give the biggest preliminary award to Intel — which Commerce Secretary Gina Raimondo has called “an American champion” — only to see the Silicon Valley pioneer disclose profound business problems earlier this month. It plans to slash more than 15,000 jobs as sales decline, and Intel’s stock is trading near its lowest level in more than a decade.

Yet Intel, while crucial, isn’t everything. The more fundamental question is whether the U.S. can sustain momentum across the broader undertaking. Industry leaders have always cautioned that $39 billion isn’t actually that much. Companies will need to find more than 160,000 workers. And the country is heading toward a presidential election that only adds uncertainty.

At the center of it all is Mike Schmidt, who runs the Commerce Department’s 175-person Chips Program Office, or CPO. His team — formed with talent from Washington, Wall Street and Silicon Valley — has one primary task: reducing reliance on Asia, and particularly Taiwan, for the tiny electronic components that power everything from microwaves to missiles.

Both American and foreign companies are now “investing at major scale in semiconductor manufacturing in the United States,” he said in an interview, and that alone is a tremendous milestone. “If you could go back two years and tell us that we’d be where we are now, I would take it 100 times out of 100.”

A top priority is securing at least two large manufacturing clusters for leading-edge logic chips, or the brains of devices. Officials also want high-volume sites for advanced packaging, the process of encasing chips and connecting them to other hardware. And they’re seeking increased production of less advanced semiconductors known as legacy chips, an area where the U.S. worries about China’s growing capacity, as well as cutting-edge DRAM memory, which handles data storage and is essential to the AI boom.

On all fronts, there’s progress. In the past several years, nearly a hundred companies have pledged to spend roughly $400 billion on U.S. facilities. Over half of that comes from a trio of top chipmakers — TSMC, Intel and Samsung — that are planning a slew of new chip fabrication centers, or fabs, to manufacture their most cutting-edge technology.

But most of those semiconductors will pass through Asia. CPO couldn’t persuade TSMC to bring packaging capacity to its site in Arizona, according to people familiar with the conversations. And though a supplier is building nearby, many chips will be shipped overseas for a key step of the process. That’s true for much of the U.S. semiconductor ecosystem — a dynamic that a senior Commerce official warned “creates supply chain and national security risks that we just can’t accept.” (TSMC and CPO declined to comment on their talks.)

Schmidt

Asked what share of U.S.-made chips could be packaged here based on current plans, Schmidt didn’t offer a specific number. “The supply chains will continue to be global,” he said, adding that the U.S. has made a “strong foothold.” CPO has funded five packaging-related projects so far, one of which will focus on chips sent here from South Korea.

The Biden administration also has struggled with how to promote memory chips, a commoditized product that carries low profit margins — meaning that scale matters for commercial viability. Samsung floated the idea of building a Texas memory fab, people familiar with the matter said, as part of a broader investment pitch that would have been more than double its current commitment. CPO decided against funding it. (Samsung and CPO declined to comment. Most of the dozens of people interviewed for this story requested anonymity to discuss sensitive conversations.)

Instead, officials rested their ambitions on Micron’s memory-chip projects in Idaho and upstate New York — a decision some attribute partly to Senate Majority Leader Chuck Schumer, who once listed himself as one of five reasons to invest in the Empire State. Micron is planning as many as four fabs in the Syracuse region over 20 years. But CPO was seeking projects that will start production by the end of the decade and only funded the first two. That will “provide the foundation,” Schmidt said, to make ongoing investments attractive.

A full build-out is far from a sure thing. The Environmental Protection Agency is concerned that Micron’s proposed site “does not currently comply” with the Clean Water Act, according to a July 30 letter reviewed by Bloomberg. It notes a significant impact on wetlands and says Micron is working on — but hasn’t submitted — a comprehensive mitigation plan.

The company is now slow-walking plans for its third New York fab, people with knowledge of the matter said, as it talks to Tokyo officials about adding another facility in Japan.

“Micron is taking the first steps toward our vision of a four-fab complex in New York,” the chipmaker said in a statement, and is committed to planned investments there and in Idaho. The New York site will “likely result in wetland impacts,” it said, adding that permitting applications are underway.

Then there’s Intel. Pat Gelsinger, the struggling company’s CEO, has hitched his ambitious turnaround plans to money from the CHIPS Act — and already called for a “CHIPS II.” The crown jewel of the expansion is a sprawling Ohio complex that Intel has said will become the world’s largest chipmaking facility, and which President Joe Biden has called a “field of dreams.” Pulling it off was always going to be a challenge. There isn’t much of a semiconductor ecosystem in the state, and it’s not clear whether Intel has lined up any customers.

Even after announcing layoffs and cutting the company’s long-prized dividend, Gelsinger has said Intel remains dedicated to its manufacturing road map. Schmidt, asked about Intel’s most recent earnings report, pointed to those remarks. And if there are setbacks, the CHIPS Act has a built-in insurance policy: Companies won’t receive money until they hit specific construction and production benchmarks, and CPO can claw back already-disbursed funds if projects are never completed.

Intel CEO Pat Gelsinger (left) and President Joe Biden arrive for a ceremony at the groundbreaking of Intel’s new manufacturing facility near New Albany, Ohio, in September 2022. (Gaelen Morse/Bloomberg News)

“Intel is prioritizing our core investments that are laying the groundwork for our future, and we are committed to our existing U.S. projects in Arizona, New Mexico, Ohio and Oregon,” the chipmaker said in a statement.

But there’s more at stake if Intel can’t deliver. The company is also the sole intended beneficiary of a $3.5 billion CHIPS Act program to make advanced electronics for the military, an effort called the Secure Enclave. The idea is to create a separate, locked-down area within Intel’s factories to make semiconductors for top-secret defense purposes. It hss caused a furor in Washington, in part because it entrusts the responsibility to one company.

But the real drama began on a Thursday in February, when the Defense Department informed Commerce that it would no longer foot its $2.5 billion share of the Secure Enclave bill. Days later, lawmakers directed CPO to shoulder the full burden. CPO ultimately helped cover the shortfall by scrapping a program for commercial research and development, which meant it couldn’t fund a $4 billion Applied Materials Inc. project in the heart of Silicon Valley. (Officials intend to revive that R&D initiative if they get more money from Congress, but attempts at a $3 billion boost have stalled.)

For many in government and industry, the episode felt like a prime example of Washington getting in its own way. (The Pentagon, Commerce Department and Intel declined to comment.)

While most CHIPS Act promises are just that — promises — companies have also committed real money to groundbreakings across the country. The first CHIPS Act-supported production could start by the end of this year, CPO said, without specifying which firm might reach that target.

Jeff Loftus of FMCSA joins TT’s Seth Clevenger to discuss the current outlook on ADAS technology and how it will affect the industry at large. Tune in above or by going to RoadSigns.ttnews.com.

Several major sites have seen at least a small delay, on top of project timelines that are already longer than they would be in many other parts of the world. Companies hoped for a reprieve from often-lengthy environmental reviews, but Republicans blocked that legislation. TSMC — which has long thrived at home, thanks in part to ample government help — spent months resolving a spat with local unions. Other firms’ woes have ranged from cement plants to endangered bats.

CPO is also contending with a labor provision called Davis-Bacon, which sets prevailing wages for federally supported construction. The Department of Labor wants semiconductor companies to retroactively apply new wage floors for workers who started before projects won CHIPS Act awards, people familiar with the situation said. The chipmakers say compliance alone could cost millions and introduce significant liability, as they have to find contractors who left sites months or years ago — to say nothing of the actual back pay. The issue has stalled several negotiations, according to the people, as CPO and companies work toward final award agreements.

“This is the first time that Davis-Bacon has applied to the construction of semiconductor facilities, and we are working constructively both with our applicants and the Department of Labor to implement it in a new context,” a Commerce representative said. The Department of Labor did not respond to a request for comment.

Two years of President Biden and Vice President Harris’ CHIPS and Science Act - recapped in under 60 seconds by @SecRaimondo. pic.twitter.com/nU7xEa1fZV — The White House (@WhiteHouse) August 9, 2024

The White House and many Democrats also want semiconductor subsidies to be a boon for unions, and labor leaders have made it clear they expect to benefit. In some cases, they have: Eight chip construction sites, including Micron’s, are covered by labor agreements or have a heavily unionized workforce. The fabs themselves are a separate challenge. Intel met with the Communications Workers of America but declined to move forward with labor peace talks; Micron committed to a CWA dialogue, but the union said it’s been “disappointing” so far.

“All of us workers — we’re taxpayers,” said Robbie Garecht, 36, who’s among dozens of employees demanding better pay and safety measures at an Analog Devices Inc. factory that’s vying for federal funds. “That’s our money.” (The company said it respects employees’ right to express their views and aims to address their feedback.)

Yet those hurdles haven’t caused any major chipmakers to eschew the subsidies altogether. Nor have requirements for things like child care services at large factories — a minor theme in negotiations despite weeks of Washington hand-wringing — or CPO asking companies to launch apprenticeships, for which awards only stipulate a reasonable effort, according to people familiar with the talks. The lion’s share of negotiating time goes to dollar amounts and milestones, Schmidt said: “I think we made actually tremendous progress in a pretty short period.”

To make it all worthwhile, the fabs need workers, from engineers who design chips to technicians who make them. Even under optimistic projections, the U.S. semiconductor industry will be short 59,000 engineers over the next five years, according to McKinsey & Co., and possibly as many as 77,000. There’s real concern that without immigration reform — and a cultural shift that draws more Americans into hardware innovation — the country could build a bunch of fabs, then struggle to maintain leadership. A pessimistic outlook for technicians similarly sees a 69,000-person gap.

Biden signs into law the CHIPS and Science Act of 2022 at the White House in Washington on Aug. 9, 2022. (Carolyn Kaster/Associated Press)

But it’s entirely possible to avert a long-term technician shortage, McKinsey says, in part by transitioning people from similar industries. In places like Ohio, there’s a large labor pool with transferable skills, a 2023 study found. A lack of such workers in Texas, meanwhile, presents a more acute challenge.

A lot hinges on training. Colleges have launched or expanded more than 80 semiconductor-related programs since the CHIPS Act passed, CPO says; the question is whether they can scale fast enough. In upstate New York, a partnership between Hudson Valley Community College and Rensselaer Polytechnic Institute offers two years of instruction — and a GlobalFoundries Inc. internship — to an inaugural cohort of six students.

In Arizona and Oregon, meanwhile, Intel has hired 220 students from its Quick Start initiative, which provides two weeks of industry exposure. But the majority of around 900 Arizona graduates haven’t landed chip-related jobs, in part because new factories aren’t up and running. Intel hopes to hire more when its Fab 52 opens next year, the company said. In the meantime, the Greater Phoenix Economic Council has been working to connect those students to 64 other semiconductor-related employers in the region.

Want more news? Listen to today's daily briefing above or go here for more info

Looming in the background is November’s presidential election. CPO aims to allocate the remaining grant money — a few billion dollars — by the end of this year. Conservative Hill staffers and think tankers, meanwhile, are plotting how they might rescind what they consider “woke” CHIPS Act rules if Donald Trump wins back the White House. That’s all while Trump, whose administration first recruited TSMC in 2020, questions the wisdom of supporting Taiwanese firms’ investments. (He did not name TSMC.)

But the CHIPS Act has always been a bipartisan effort. And in private, a few GOP lawmakers who voted against it have begrudgingly come on board, said Sen. Todd Young (R-Ind.), an original architect of the bill. “Some are embarrassed,” he said, by how much it’s accomplished.

Asked whether political volatility could make it harder for the U.S. to achieve the legislation’s goals, Schmidt paused.

“Our success as a program has been built in large part on the strength of the relationships we built with our applicants,” he said. “Those aren’t always easy relationships, but they are relationships where we’ve built a lot of trust.”