Clarios Pilots AI-Enhanced Battery Monitoring for Fleets

[Stay on top of transportation news: Get TTNews in your inbox.]

HANOVER, Germany — Clarios, the world’s largest battery manufacturer for mobility, is introducing technology that predicts battery health, informing drivers, fleet managers and maintenance teams of a battery’s status. This knowledge can help heavy-duty fleets decrease operating costs, improve uptime and reduce their carbon footprint.

“Battery failure can account for as much as 20% of a truck’s downtime,” said Federico Morales-Zimmermann, vice president and general manager, global customers, products and engineering at Clarios.

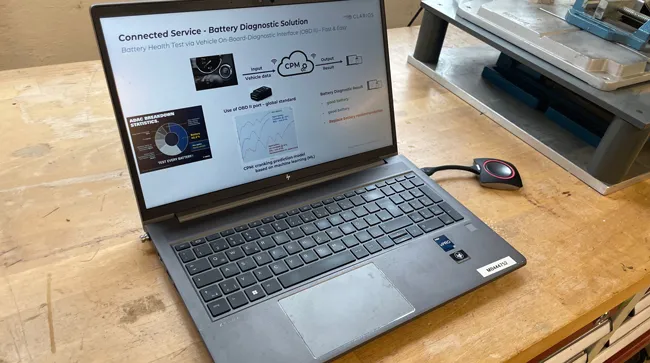

To address this issue, Clarios has developed Connected Services, a system that combines artificial intelligence, machine learning, cloud computing and proprietary algorithms. Brian McKay, chief technical officer for Clarios, explained that the technology provides real-time data to fleet managers, enabling informed operational decisions.

The company is currently piloting the technology with commercial fleets, with pricing to be determined based on these trials. Clarios showcased its solutions at IAA Transportation.

Brian McKay, chief technical officer for Clarios. (Mindy Long/Special to Transport Topics)

One of the key challenges in battery performance is the potential for rapid failure, which McKay describes as a “cliff.” Batteries vary significantly, with their life span affected by numerous factors including weather, operations, driver behavior and age. This variability makes it difficult for fleets to anticipate when replacements or issues might arise.

READ MORE: Low-Voltage Power Demands Are Driving New Battery Solutions

McKay elaborated on how the new technology addresses this challenge: “Who’s telling you to replace them? That’s really where the software capabilities, the battery health and the state of charge come in so the batteries can raise their hand and say, ‘Hey, I’m not feeling great. It’s time to replace me or adapt me.’ ”

The system analyzes historical micro-aging events and operational environments, using algorithms to calculate cumulative aging and battery decomposition. “We are pulling from known events and have data about exactly what is happening,” McKay explained.

(Mindy Long/Special to Transport Topics)

By leveraging AI and machine learning, the technology can detect root causes of micro-aging events and self-adapt multi-battery controls. “The more inherent data the vehicle has, the more accurate it will be,” McKay added.

This capability allows fleets to extend battery life by delaying the performance cliff. Connected batteries will help fleets maximize battery lifespan and get full value from them.

The predictive nature of the technology also increases convenience for fleets. McKay noted, “We could probably time that to your next oil change or when you need to get your windshield wipers replaced or when you need to get your tires replaced. The data is available. So now it’s about getting that data back into your hands.”

(Mindy Long/Special to Transport Topics)

Another significant benefit of the system is its potential to reduce unnecessary idling. According to Markus Hoh, senior manager of advanced engineering for Clarios, about 80% of current idling is unnecessary. The system provides alerts to drivers, indicating when to start and stop the engine to maintain optimal battery charge while still supporting heating and air conditioning systems.

Pilot projects have already demonstrated promising results, with Clarios observing a 40% reduction in unnecessary idling time. This decrease translates to reduced fuel consumption and lower CO2 emissions. The system, which connects via a CAN bus, is compatible with existing telematics interfaces.

Markus Hoh, senior manager of advanced engineering for Clarios. (Mindy Long/Special to Transport Topics)

Looking ahead, Clarios is developing a dongle device that can plug into a vehicle’s OBD-II port to help diagnose and troubleshoot non-connected batteries. “The idea is that testing a battery should be easy and safe,” Hoh said, adding that the goal is to also make it fast.

The dongle would enable technicians to troubleshoot batteries and get insights without removing them from the vehicle, saving time and effort. It is expected to be available next year.

Want more news? Listen to today's daily briefing below or go here for more info: