Component Manufacturers Unveil Green Tech at IAA 2024

[Stay on top of transportation news: Get TTNews in your inbox.]

HANOVER, Germany — Manufacturers exhibiting at IAA Transportation 2024 showcased new innovations to help reduce carbon emissions in the trucking industry.

“Decarbonization is the dominating topic at IAA and in transportation around the world,” said Peter Laier, a member of the ZF Group board of management.

About 1,700 exhibitors from more than 40 countries took part in IAA. Cummins CEO Jennifer Rumsey said the event shows the industry is changing and that customers demand optionality and functional solutions to lower emissions.

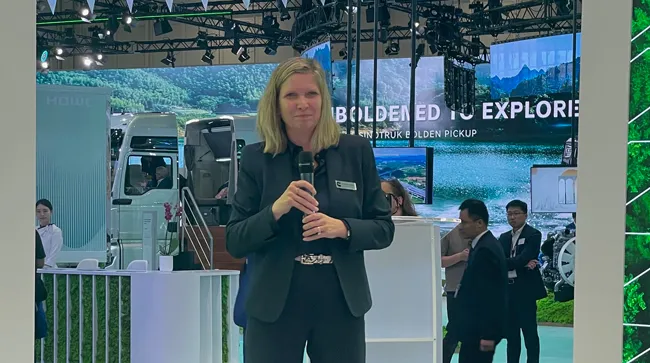

“Our customers are running real businesses, and our products are helping them do the difficult work needed to power economies, move goods around the world and provide good jobs for people in our communities,” she said during a press conference. “As we move closer to these new, stricter vehicle-level standards, power technology decisions are becoming tougher and more complex.”

Cummins CEO Jennifer Rumsey said CO2 regulations will not be met with a single solution. (Mindy Long/Special to Transport Topics)

Cummins Moves Toward Destination Zero

Cummins has embraced a “Destination Zero” strategy, which Rumsey said is a multilevel approach that leverages its integrated suite of power offerings across its core and Accelera by Cummins systems.

“Last year, we allocated a record $1.4 billion in research and development,” Rumsey explained. “These investments are enabling greenhouse gas reduction through improvements in fuel-economy performance of diesel and natural gas-powered vehicles and related components, as well as development activities for hydrogen engine solutions, battery-electric, fuel cell and hydrogen production technologies.”

Cummins showcased some of its latest advancements in powertrain technologies, including after treatments, rear drive axles, e-axles and brakes. (Mindy Long/Special to Transport Topics)

Cummins displayed several new technologies, including its integrated driveline concept that can provide flexible power solutions for advanced diesel, diesel-hybrid and zero-carbon hydrogen.

“There is not one solution that will service every customer. It depends on the application and the need,” Rumsey said.

The driveline can integrate Cummins’ HELM engine platforms.

“HELM stands for high efficiency, lower emissions, multiple fuels, and is the product brand for our industry’s first fuel-agnostic engine platforms,” Rumsey said. “Think of these engine platforms as the building blocks our customers can take and design what works for them best today and in the future.”

ZF’s booth featured interactive displays for attendees to explore new solutions. (ZF)

ZF Highlights E-Mobility Services

While speaking at IAA, Laier said ZF is developing customized solutions for its customers and “has a unique portfolio” to meet their needs, noting ZF’s acquisitions of TRW and Wabco. “ZF is increasingly strengthening its position as a pacesetter in the commercial vehicle industry. Our past investments in our product development with a firm focus on innovations are now paying off.”

ZF displayed its new modular e-mobility platform. It consists of different e-motors, corresponding inverters, a 3-speed transmission and its associated electrical components. This comprehensive modular package gives manufacturers the flexibility to configure the e-drive system to their specific requirements.

Laier expects e-drive production in commercial vehicles to double in the next 12 months and said ZF has confirmed orders worth 5 billion euros (about $5.6 billion). “By 2026, we will be the No. 1 manufacturer of e-mobility solutions in Europe,” he said, adding that ZF anticipates growth of e-drive systems in the Asia-Pacific and North America markets.

The ZF TrailTrax electrified trailer concept that integrates the AxTrax 2 electric drive axle from ZF and a modular battery system with the trailer EBS. (ZF)

During IAA, ZF and Foton, a commercial vehicle company in China, signed a letter of intent to introduce ZF’s new hybrid transmission for commercial vehicles to the Chinese market. They already have a joint venture set up to deliver the TraXon automatic transmission and electric drives in China.

ZF also displayed its TrailTrax electrified trailer concept that integrates the AxTrax 2 electric drive axle from ZF and a modular battery system with the trailer EBS.

“A conventional diesel and electric trailer is a kind of hybrid you could create,” Laier said while speaking with North American journalists.

TrailTrax reduces CO2 emissions by up to 16% when the trailer is used with a diesel truck. That figure can increase to 40% when the trailer is used with an electric truck, he said.

ZF also unveiled its new Hydrogen Recirculation Blower, which is designed to optimize hydrogen levels for fuel cell-powered vehicles by recirculating unused hydrogen to improve hydrogen consumption and performance while using minimum power from the fuel cell system.

Arnd Franz, CEO of Mahle, said the company’s newest solutions will dramatically increase performance of BEVs and FCEVs. (Mahle)

Mahle Moves Forward with BEV and FCEV Technology

Mahle, a Stuttgart, Germany-based manufacturer of components and systems for battery-electric and fuel cell vehicles, used IAA to showcase its complete system for a fuel cell truck, with fuel cell peripherals, thermal management and a fully functional heavy-duty electric axle.

“BEV isn’t the only solution,” CEO Arnd Franz said during a roundtable discussion. “Obviously, BEV will play a major role, but we believe hydrogen will be an important part of trucking.”

Battery-electric and hydrogen fuel cells place high technical demands on vehicles, and Mahle has developed a fuel-saving evaporative cooling system for BEVs and FCEVs. The system uses the cooling effect of evaporating water that is sprayed onto the coolant cooler via a grating, creating the optimum temperature control for the fuel cell.

Mahle’s new evaporative cooling system provides up to 50 kW more cooling capacity. (Mindy Long/Special to Transport Topics)

The company also has released a high-performance bionic fan that makes electric trucks quieter at full load or during rapid charging. The fan reduces a truck’s fan noises by up to 4 dB(A), more than halving the sound pressure level.

Mahle has integrated two SCT (superior continuous torque) electric motors with liquid management systems in the heavy-duty electric axle. The e-axles provide a continuous output of 480 kilowatts and efficiency of 92%, which Franz said makes it ideal for battery-electric trucks and fuel cell applications.

“The internal cooling system provides the motor with enough cooling to avoid de-rating,” Franz said, adding that manufacturers have to find the right solutions for fleets to drive adoption. “This is only possible when we find solutions that are competitive.”

The growing electrification of the transportation sector has created considerable potential for Mahle, and Franz said the volume of Mahle components per vehicle is twice as high in the case of battery-electric trucks as with conventional internal combustion engine trucks and will be doubled once again in fuel cell trucks.

Currently, Mahle is doing business with 120 international commercial vehicle brands in the on-highway and off-highway segments.

“We are committed to shaping a sustainable transportation sector with a view to strengthening the foundations for economic growth,” Franz said.

Want more news? Listen to today's daily briefing below or go here for more info: