Freight Industry Confronts Climate Change

[Find the latest in equipment & maintenance: Explore this quarter's issue of Calibrate]

The North American Council for Freight Efficiency coined the term “Messy Middle.” It refers to the fact that there is more than one way to attack the problem of climate change in an environment in which there is a wide range of solutions.

Jeff Seger, owner of InProTech Solutions and a member of NACFE, is an independent consultant who has industry experience with major players leading turnaround businesses and taking new technology to market. His firm helps many types of companies transition to clean energy reliably and profitably. He says the Messy Middle is a period when decarbonization and other solutions are being offered. Seger explains that the Messy Middle runs from A to Z.

“A refers to alternate fuels like natural gas, propane and even hydrogen used to power a modified internal combustion engine, and Z refers to zero-emission vehicles like battery-electric and hydrogen fuel cell electric equipment,” he said. “D [diesel] sits closer to the present, where a fleet takes a more traditional approach making the best of what’s already available and optimizing it, plus adopting the upcoming 2027 equipment.”

The first step for those who need to show progress is in the simple things, such as improving aero, standardizing electronic parameters like those that determine shift points, and aggressively teaching drivers to be more efficient and use cruise control. There are also possibilities such as using renewable fuels.

Baxter

Because there is a series of regulations referred to as Advanced Clean Fleets that applies to fleets and sustainability targets that your customers need to meet, there’s no escaping the need to adapt to a greener future. Seger says you need to do the following to select the best greener powertrain for your operation:

• Look at the duty cycle and determine which powertrain is best

If an alternative fuel looks good, you need to know if the infrastructure is available for refueling where your vehicles run and how easy it will be for your shop to maintain the equipment that uses it and adjust to doing so.

If it will be a zero-emission vehicle, you’ll need to know about charging infrastructure for battery-electric vehicles and hydrogen refueling points for fuel cell electric vehicles — and, of course, about training and equipping your technicians and shops to repair it.

• Make simple changes to improve fuel economy

Even if your fleet is small and capital for new equipment is a major issue, there still are many opportunities to improve a fleet’s performance in this area.

Seger

Seger points out that the ultimate destiny of green trucking is likely to prove to be a combination of BEVs running on electricity generated by windmills, solar panels and new types of nuclear reactors for shorter hauls, and, for over-the-road trucking, fuel cell electric vehicles running on hydrogen generated with the same sources of electric power using electrolyzers to separate hydrogen from water.

In the meantime, there are more familiar solutions that require a smaller leap to adopt. Seger strongly recommends that truck fleets work hard to become aware of all the technological risks when deciding whether to stick with diesel, adopt something powered by somewhat different ICEs using greener fuels or going all the way to truly green powertrains. Seek help from someone who isn’t so busy managing their fleet that they can’t spend a lot of time assessing the risks and potential benefits of each new technology.

More Q4 Calibrate

►Military Vets Fill Technician Roles

►Freeze: Spotlight on Technicians

►Buses Leading Race to Electrification

►What's Next for Alternative Fuels?

►Baxter: Confronting Climate Change

►TMC Corner: Cybersecurity Issues

Explore the Issue!

Acquiring 2027 diesels will take you forward, but they will be significantly more complicated in order to meet the EPA 2027 low nitrogen oxides and upcoming Greenhouse Gas Phase 3 standards. NOx will be reduced by making the present selective catalytic reduction concept work better during warmup and low loads. This will be done with design features such as adding a second catalyst right near the turbo, adding dual dosing of diesel exhaust fluid, heating and insulating the catalyst(s). And possibly adding cylinder deactivation, which deactivates various numbers of an engine’s six cylinders under light loads in various sequences, called “skip-firing,” to reduce airflow and increase efficiency and the temperature of the exhaust. It helps NOx by speeding warmup and keeping exhaust hotter at low loads to get and keep the SCR working while improving fuel economy under low-load conditions for GHG standards.

President Biden and the @EPA are driving towards a clean transportation future with new proposed vehicle emissions standards for models 2027 and beyond.

These standards would reduce climate pollution, lower costs for families, and reduce dependence on foreign oil. https://t.co/jHc3eVyc98 — The White House (@WhiteHouse) April 12, 2023

Makers of model year 2027 diesels may add hybrid features on to the drivetrains of smaller engines for carbon dioxide reduction. Hybrids employ motor-generators to generate electricity during braking and then return it to the powertrain when needed.

Interim solutions include fueling with biodiesel blends or 100% biodiesel, converting medium trucks to propane, or using compressed or liquefied natural gas in Class 8s. Cummins in 2024 will introduce its X15N, previously discussed here, a game changer for natural gas that will satisfy drivers while saving fuel versus earlier natural gas engines by providing diesel-like torque. Spark-ignited natural gas engines provide far simpler emissions control with a three-way catalyst. They can easily meet the EPA 27 NOx and particulate matter levels.

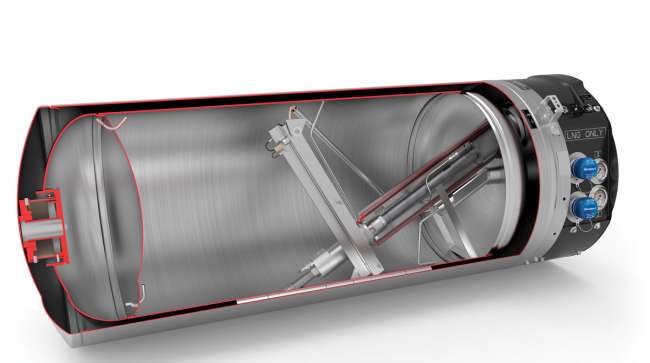

Engines converted to natural gas by Westport Fuel Systems use LNG and diesel-like high pressure-direct injection, offering diesel-like efficiency. Volvo has adapted this technology to its 13-liter diesel and is doing on-road testing in Canada now.

What does it take to become the best technician in the country? Hear from two experts who supervised the exams at TMCSuperTech. Tune in above or by going to RoadSigns.ttnews.com.

All engines powered by natural gas can use renewable natural gas, which consists mostly of methane recovered from agricultural sources and landfills. Since methane is 30 to 80 times as potent a greenhouse gas as CO2, the effect on the climate is positive, causing it to be categorized as “carbon-negative” by the California Air Resources Board and many in the industry.

Hyliion has a hybrid powertrain that combines a 12-liter, spark-ignited engine fueled by compressed natural gas that drives only a generator with electric tandem axles and a battery pack. It can drive for 75 miles on one charge and then uses the engine to provide power, while the electric axles both augment horsepower on hills or during acceleration and recover energy by employing regenerative braking to charge the batteries, thus extending range. Tractors powered by the system qualify as a near-zero-emission vehicle.

Seger has explored the supply chain for BEVs in a significant study and found potential storm clouds on the horizon. If demand is high enough, “We could get ahead of ourselves” in terms of the availability of the required precious metals, he said. But he also is optimistic about battery performance, sees a future for solid-state batteries and said some companies are working on electric motors that don’t even need magnets, which require precious metals.

Want more news? Listen to today's daily briefing above or go here for more info

Fleets that are exploring BEVs will need to answer questions about whether the advanced Tesla and Nikola designs, which may prove to be more efficient and offer longer range, are difficult to integrate into their maintenance systems. Will the more conventional electric powertrains made by traditional truck manufacturers prove their mettle in the shop?

The solution for linehaul, over-the-road Class 8s will be hydrogen fuel cell electric trucks, with ICEs that run on hydrogen also becoming available as an interim solution. Both the electrolyzers that create hydrogen energy from green sources and hydrogen fuel cells, as well as ICEs, are far less efficient than battery-electric systems. As a result, it takes about three times the energy to run on hydrogen. One of the technological risks for BEVs and FCEVs is the power grid’s ability to provide enough green energy and distribute it for on-road use, and the risk is thus considerably greater for hydrogen-fueled vehicles.

Seger says that effectively cooling all the systems in BEVs and FCEVs will be problematic and mean technological risk for developers and the maintenance department, too.

Of course, these problems likely will be solved, as massive joint ventures composed of leading industry companies will be confronting them. Daimler and Volvo have formed Cellcentric GMBH to develop their future technology, while Paccar has selected Toyota as its fuel cell supplier. Cummins Accelera, Daimler Trucks and Paccar have just formed a joint venture to partner in accelerating and localizing battery cell production and the battery supply chain in the United States. Thus, it is likely a truly green future will arrive, but in the meantime, there’s a lot of technological risk to consider and a bit of a minefield of choices to be navigated.