Truck Body Repair Collaborations Help Streamline Planning

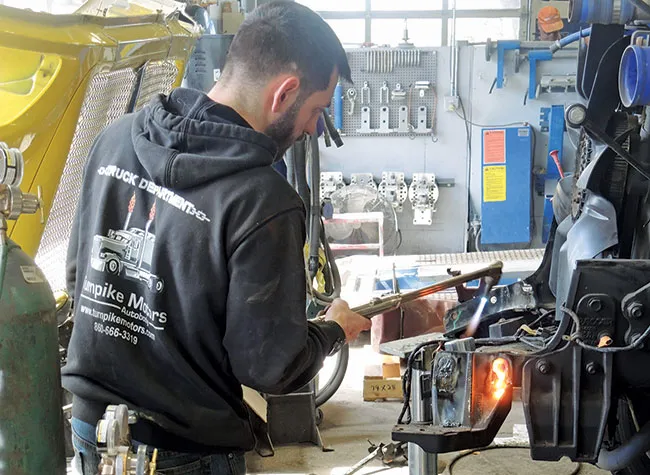

Garron Marschall, a truck tech at Turnpike Motors Autobody, performs welding repairs. One of the challenges of auto body is in recruiting, training and retaining truck technicians. (Turnpike Motors Autobody)

[Stay on top of transportation news: Get TTNews in your inbox.]

To many trucking experts, the science of restoring and repairing the body on a Class 8 commercial truck is a process of handling moving parts while performing a proper assessment and eventually restoring the unit to a safe, roadworthy state as promptly as possible.

Fred Staugh, chief maintenance officer for Hirschbach Motor Lines, a nationwide carrier, described it as simply as “you’ve got to get the vehicle to the right place.”

He explained that a “breakdown group” manages body shop-related matters for Dubuque, Iowa-based Hirschbach, which ranks No. 45 on the Transport Topics Top 100 list of the largest for-hire carriers in North America. “It doesn’t matter if the vehicle gets damaged or just needs a tire or a taillight,” he said. “The breakdown group handles all those calls.”

The carrier has one body shop to do structural repair of trailers, otherwise relying on arrangements with outside providers, including a network of some 600 parts and service locations maintained by Aurora Parts, based in Lebanon, Ind.

Hirschbach relies on a combination of Navistar International and Freightliner dealers and some independent truck body shops. “Most trailer structural repair places are not truck places and vice versa,” Staugh noted. “There’s really a defining line between truck and trailer repair facilities when it comes to structural damage.”

Steve Mignardi, vice president of on-highway market development for Daimler Truck North America, explained that fleets typically have their own network of partners for roadside assistance and repairs.

Most trailer structural repair places are not truck places and vice versa. There’s really a defining line between truck and trailer repair facilities when it comes to structural damage.

Fred Staugh, chief maintenance officer for Hirschbach Motor Lines

Image

“To determine the priority of a body repair, fleets need to consider workload, demand and technician skill level,” he said via email, adding that through DTNA’s dealer network, fleets have access to trained technicians who can repair damaged panels, straighten bent components, or replace major components such as cabs and hoods. “For efficiency, some fleets collaborate with local dealers to pre-order frequently purchased parts, such as hoods or bumpers, in the event of unforeseen issues,” he said.

For certain big fleets with deep pockets, Rush Enterprises has truck cabs in stock. “If there’s a major collision, we’ve got that part available — a fully dressed cab ready to install,” said Victor Cummings, vice president of service operations for Rush, noting that otherwise, a year or more can go by while trying to source a cab, especially for some older vehicles.

Kyle Fogle, collision center manager for Rush Truck Centers in Houston, said parts have always been a challenge on the collision side and over the past four years, they have been increasingly difficult to source. He urges body shop personnel to look for parts “far and wide,” meaning as close as the nearest other Rush facility, a distribution center within an OE network — or as far as Google, eBay or Amazon.

Wisniewski

“We utilize the fleets as well. They buy a lot of trucks, they spend a lot of money in parts and service, and a lot of times they’ve got direct-line contacts,” he said. “If the wheels aren’t turning, they’re not making any money.”

Matt Wisniewski, vice president of sales for national accounts at Aurora Parts, said it proves very difficult for dealers to stock and deliver large or long material.

“When a trailer is damaged, you’re talking about 52-foot, 54-foot material,” he explained. “That’s not stuff that’s easy to move around.”

To make it easier, Aurora Parts expanded its parts distribution network. In 2003, Aurora had the one distribution center in Lebanon, measuring about 300,000 square feet. In recent years, it has added parts distribution centers in Atlanta; Dallas; Batavia, Ohio; and Reno, Nev. This year, it is opening a new 300,000-square-foot location in York, Pa., Wisniewski said. The six sites add up to nearly 1.5 million square feet.

Material stored at an Aurora Parts distribution center. Aurora had one distribution center in 2003 in Lebanon, Ind., and has since added centers in Atlanta; Dallas; Batavia, Ohio; and Reno, Nev. Plus, another one is opening later this year in York, Pa. (Aurora Parts)

Some managers and vendors said getting delivery on a new truck sometimes takes as long as a year or more. With that in mind, some fleets are more inclined to repair a vehicle.

Since many carriers are self-insured, “they will dictate when they total a unit,” said Taylor Anderson, shop manager at the Aurora, Colo., location of McCandless Truck Center, a Navistar International dealer. Some fleets write off a unit if the damage equals or exceeds 80% of its value; some do so at 60%, he said. If a truck is determined to be worth $40,000 and the repair is $35,000, some fleets decide to fix it, judging that it’s a better option than trying to acquire a new or used unit.

Once a fleet notifies McCandless that it has a damaged unit, one or two estimators from the dealer go to examine the truck, taking 20 to 30 or more pictures and working with the body shop parts coordinator. A repair estimate is typically provided to the customer by the end of the next day, Anderson said. “When we have jobs that get dropped off here, they’re in the bay right away for quick turnaround time,” he said.

McCandless operates the body shop in Aurora and another at its location in North Las Vegas. “Most of our body parts we do stock here,” he said, adding that body techs “are trained to balance two to three jobs at the same time.”

Managing Information

To manage the vast amount of information alongside the body work and parts, Rush Enterprises uses an in-house tool called “Service Connect,” a customer portal for communication, including text messages and email; pictures of damage and repair estimates can be uploaded. All communication is in one system, and the information is archived, Cummings said.

Hirschbach relies on a combination of Navistar International and Freightliner dealers and some independent truck body shops for repairs. (Hirschbach Motor Lines)

Hirschbach Motor Lines is a customer in an Aurora Parts program, FleetPerform, that features an online “central billing apparatus” through which dealers push their estimates to carriers. “You can approve the estimates on a web portal,” Staugh said, “which takes a lot of the noise out of the system.” The process uses one format for estimates, and one format for invoices from the hundreds of dealers in the Aurora network, Staugh added.

Wisniewski said carriers in the FleetPerform program use a service locator on the Aurora website to choose one of the service locations in the network. Pictures of the damage can be uploaded into the system along with the estimate.

A fleet’s approved component manufacturers — for wheel seals, bearings, hubs and so on — are detailed in each customer’s FleetPerform account “so when the third-party provider puts the account number into the network, all of this pops up,” he said. Wisniewski added that fleets are charged the same parts prices at every location and standard repair times are the same throughout the network. However, labor rates vary based on regional or local markets. While third-party shops typically operate on a first in, first out basis, Wisniewski said, fleets that are FleetPerform customers get priority bay access.

Proper Training

The 3M training center in St. Paul, Minn., offers courses in auto body repair and paint prep and refinishing. Ben Gervais, senior manager of business development for 3M’s automotive aftermarket division, said instruction is focused on process, and noted that although the training is primarily on passenger vehicles, the “concepts are relatively consistent across vehicle classes.”

Over the past four years, one of the issues facing the collision segment has been the difficulty of sourcing parts. (McCandless Truck Center)

Jamin Woody, director of service operations for McCandless Truck Center, concurred. “There’s a lot of stuff that copies over from auto body to trucks,” he said. The 15,000-square-foot center contains welding and sanding stations, a paint booth, a paint mixing room and a space for demonstrating and teaching how to use joint adhesives, and classrooms. Each course qualifies for continuing education credits with I-CAR, the Inter-Industry Conference on Auto Collision Repair.

Also, changes in truck materials can require body shops and techs to change methods. For example, Metton, a liquid molding resin, is being used in some hoods, for instance. Compared to a fiberglass hood, a hood made of Metton is lighter and thinner and must be worked differently in the repair process, said Fogle of Rush.

Aurora Parts launched an Online Training Academy in 2016 and is continuing to develop it. Aurora asks vendors to provide resources, including YouTube videos and other instructional materials “so we can put them in this online academy,” Wisniewski said.

Fernandez

Doug Fernandez, president and owner of Turnpike Motors Autobody, an independent shop in Newington, Conn., said the key to efficiency in commercial vehicle collision repair happens after the initial appraisal, in the making of “a formal repair plan.” Turnpike Motors is equipped with a frame straightener and a paint booth for Class 8 trucks. “You fully disassemble the vehicle, identify all the damage, determine all the parts prices, activities, material requirements, what kind of resources are needed to fix it, and then create what is a full plan to fix it — a repair plan,” Fernandez explained.

As has been felt across the industry, the scarcity of technicians adds to the challenge of auto body repair and requires constant recruiting, training and retention efforts.

“You need to find people who are current and moving forward with training and equipment and technology,” said Fernandez, whose garage staffs seven technicians. “The ‘old school’ guy is not the guy anymore.”

Want more news? Listen to today's daily briefing below or go here for more info: