Staff Reporter

Verne’s Cryo-Compressed Hydrogen Tech Nears Pilot Phase

[Stay on top of transportation news: Get TTNews in your inbox.]

A 2019 Volvo VNL 760 will serve as the initial testing ground for an innovation its developer believes could increase the range and cut the cost of every hydrogen-fueled Class 8 tractor manufacturers envision building as part of the gradual decarbonization of the freight sector.

San Francisco-based Verne plans to offer truck makers — whether they are building dual-fuel, hydrogen internal combustion engine or hydrogen fuel cell electric models — the option of cryo-compressed hydrogen storage to achieve the same range as a diesel tractor.

The startup, founded in 2020, believes cryo-compressed hydrogen can offer a denser form of hydrogen storage that improves vehicle range and payload.

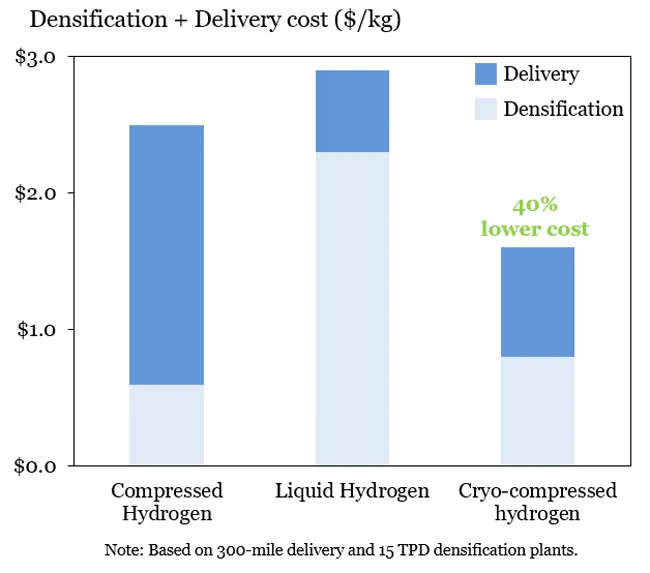

Instead of high-pressure gas or liquefied hydrogen, Verne’s solution is cold, compressed gas that offers greater density — and a lower cost of creating that increased density — than is available through liquefaction.

Verne’s system cools and compresses hydrogen to a 73 g/L internal density, a 33% improvement over liquid hydrogen and an 87% improvement over traditional 700-bar compressed gaseous hydrogen, such as that used in Nikola’s Class 8 Tre FCEV. Verne cools the gas to near minus 200 degrees Celsius and then stores it in a vacuum-sealed vessel.

The storage system is a Type 3 pressure vessel — an aluminum liner wrapped in carbon fiber, with an insulation jacket wrapped around it. Built of stainless steel, the jacket maintains the vacuum around the vessel.

(Verne)

Verne argues semis can achieve a range exceeding 900 miles, without adding any weight, using its technology.

“One of the benefits of this hydrogen storage system is we can supply one storage system to every kind of hydrogen truck,” co-founder and Chief Operating Officer Bav Roy told Transport Topics.

The hydrogen is set to be cheaper than current options because the gas no longer requires liquefaction, and more gas can be transported on a trailer to refueling locations, such as truck stops, he added.

Verne’s initial hydrogen-powered demonstration truck is a VNL 760 with a Volvo D13 engine retrofitted to use both diesel and hydrogen by Edmonton, Alberta-based Diesel Tech Industries.

DTI’s Guardian Hydrogen-Diesel System allows the engine to run on a diesel and hydrogen blend by introducing hydrogen through a multiport injection system directly into the engine’s intake runners while maintaining a reduced diesel injection process.

Verne Founders Bav Roy, COO; David Jaramillo, CTO; and Ted McKlveen, CEO. (Verne)

The system balances the fuel mix, optimizing combustion for efficiency and reduced emissions, and if hydrogen is unavailable, the system transitions back to a conventional internal combustion engine.

“This collaboration allows us to maximize onboard hydrogen storage while maintaining the flexibility and reliability of the diesel engine,” DTI Chief Operating Officer Rebecca Goldsack said.

“The seamless retrofit of this dual-fuel solution — without altering the truck’s wheelbase — meets our customers’ demands for extended range and fewer tanks, all while enabling the use of sleeper cabs,” Goldsack said.

Verne expects to begin testing the truck in advance of multiple commercial pilots. The company plans to conduct demonstrations and commercial pilot programs with truck manufacturers and fleets in Canada and the U.S. using dual-fuel engines, hydrogen combustion engines and hydrogen fuel cells.

McLeod Software CEO Tom McLeod explores the potential for artificial intelligence to boost efficiency and build resilience. Tune in above or by going to RoadSigns.ttnews.com.

Pilots will start in early 2026, Roy told TT, adding that the company is in the development stage for its pilots.

Partners will include a “well-known brand” of FCEV trucks, said Roy, while declining to provide further details or name names, although a number of graphics on the company’s website include a Kenworth-badged semi. The Paccar unit offers a T680 FCEV regional-haul semi.

Once the pilots are underway, Roy said Verne plans to build a manufacturing plant in the U.S. The company is in the late stages of selecting a site, he said, adding that the facility would build 2,000 to 3,000 systems per year initially.

So far, Roy said, Verne has built fewer than 20 storage systems. The VNL 760 received the second to be fitted to a vehicle. Verne has 18 full-time employees at the moment.

That said, expansion could be quick as Verne’s supporters have deep pockets. The company’s initial steps have been funded by heavyweight backers, including Amazon’s Climate Pledge Fund, Florida-based utility NextEra Resources, a venture capital fund run by equipment giant Caterpillar, United Airlines’ Ventures Sustainable Flight Fund and transportation-focused investment group Trucks Venture Capital.

Want more news? Listen to today's daily briefing below or go here for more info: