Staff Reporter

Cellcentric Begins Pilot Hydrogen Fuel Cell Production in Germany

[Stay on top of transportation news: Get TTNews in your inbox.]

Cellcentric began pilot production of hydrogen fuel cells June 20 at its Esslingen plant in Germany, the joint venture between Daimler Truck and Volvo Group said.

The JV plans to develop, produce and distribute fuel cell systems on an industrial scale in the German state of Baden-Wuerttemberg.

Cellcentric has three facilities in Baden-Wuerttemberg — Nabern, Stuttgart-Untertuerkheim and Esslingen. It also has a site in Burnaby, British Columbia.

The partnership between truck manufacturers that supplied a combined 56.4% of U.S. Class 8 trucks sold in 2023 aims to start supplying fuel cells on a large scale by the end of this decade.

Daimler Truck is the parent company of Freightliner and Western Star, while Volvo Group is the parent company of Volvo Trucks North America and Mack Trucks.

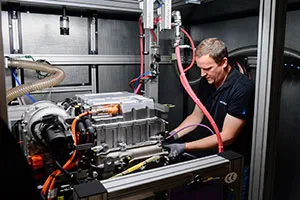

Assembly of the BZA150 generation cell, which is close to entering series production. (Cellcentric)

“The opening of our pilot production facility in Esslingen today is not the end point of large-scale production, but rather the blueprint for the next step. In the coming years, we will continue to consistently drive forward the industrialization and scaling of production of fuel cell systems at the Weilheim site,” Cellcentric Chief Commercial Officer Lars Johansson said.

“Fuel cell technology is a well-proven solution for CO2-neutral, long-distance, heavy-duty transportation. However, it has not yet been produced on an industrial scale, which is precisely the key to achieving economies of scale, optimizing the total cost of ownership and putting Cellcentric in a solid competitive position in the long term,” he added.

More than 100 employees work at Cellcentric’s production facility in Esslingen at a site with more than 10,300 square meters of production, logistics and office/administration space.

Cellcentric plans to establish the necessary production processes at the site in advance of the start of serial, industrial output of fuel cell systems.

A key milestone for the climate-neutral transport of tomorrow: #cellcentric GmbH & Co. KG inaugurates pilot production for #FuelCell systems, taking another significant step towards large-scale production.

Press release: https://t.co/8XD4GEPqFx#DaimlerTruck #cellcentric pic.twitter.com/5pF92eAOuG — Daimler Truck (@DaimlerTruck) June 20, 2024

The production steps comprise:

- Ink mixing and coating: Mixing of raw materials to produce a dispersion for subsequent roll coating.

- Membrane electrode assembly: The roll-to-piece process assembles and puts together the components of the individual cell.

- Sealing: Injection molding process applies seals in fully automated process.

- Stacking: Automated stacking of the fuel cell stack.

- Assembly

A view of the assembly line at Cellcentric's manufacturing plant in Esslingen, Germany. (Cellcentric)

At present, Cellcentric’s BZA150 generation fuel cell is close to series production, and pilot versions have been tested by the company’s shareholders.

However, in May, Cellcentric teased the arrival of a smaller, more powerful and efficient fuel cell system. Serial production of the NextGen fuel cell system is scheduled to begin at the end of the 2020s, the company said.

The NextGen fuel cell system has peak power in excess of 350 kilowatts and is expected to provide fuel consumption savings of 20% compared with the BZA150 generation cell. It is expected to have a lifetime of around 25,000 operating hours.

Meanwhile, Daimler Truck and Volvo Group are ramping up testing of their hydrogen fuel cell vehicles and the infrastructure they hope will facilitate mass production and adoption of the trucks.

Daimler Truck is set to test the Mercedes-Benz GenH2 Truck in the second half of the year with some of Europe’s largest fleet owners — Amazon, Air Products, Ineos, Holcim and Wiedmann & Winz. Fuel cell systems for the GenH2 trucks are provided by Cellcentric.

The GenH2 truck is based on a conventional Mercedes-Benz Actros cabover longhaul truck. It has two liquid hydrogen tanks and a fuel cell system.

Cellcentric's hydrogen fuel cell plant in Esslingen, Germany. Cellcentric is a joint venture between Daimler Truck and Volvo Group. (Cellcentric)

And in partnership with industrial gas giant Linde, Daimler Truck is looking to establish a common refueling standard for hydrogen-powered trucks, the sLH2 initiative.

The first sLH2 refueling station opened in February in Wörth am Rhein, home of Daimler Truck’s flagship manufacturing facility.

Plans for sourcing of the green hydrogen also are underway, with deals inked earlier in June with Japan's Kawasaki Heavy Industries and in January with UAE-based energy giant Masdar.

Corey Cox of the Tandet Group of companies discusses how early AI adopters are beginning to harvest the latest wave. Tune in above or by going to RoadSigns.ttnews.com.

Daimler Truck aims to offer a full lineup of vehicles that are CO2-neutral in its core markets of Europe, the U.S. and Japan by 2039.

Volvo Trucks plans to offer hydrogen fuel cell and hydrogen-powered internal combustion engine configurations of its semis.

Those semis include Volvo Trucks North America’s flagship VNL tractor, which launched in January and will be the platform for fuel cell, hydrogen ICE and battery-electric models.

VTNA lifted the curtain June 20 on the first battery-electric prototype VNL at its Dublin, Va., factory.

Volvo tested its fuel cell trucks for the first time on public roads in May. The company showcased the fuel cell electric trucks for the first time in 2022 and plans to begin testing with customers in 2025.

Want more news? Listen to today's daily briefing below or go here for more info: